Service and Maintenance of Material Testing Machines

To ensure the reliable function of your material testing machines, regular service and maintenance according to ISO standards are essential. This ensures that your devices continue to deliver precise results and that costly breakdowns become a thing of the past. We offer you a professional maintenance and repair service, so your machines remain ready for use and durable.

Modernization and Overhaul

Through professional modernization and/or overhaul, we bring your reliable testing machines up to the latest standards of technology.

Repair and Maintenance

To enhance the operational reliability of your machines, we are happy to assist with professional repair and maintenance services.

Spare Parts and Accessories

For our repair and maintenance services, we keep a large inventory of spare parts and accessories, even for machines whose manufacturers no longer exist.

Accredited Calibration according to DAkkS

In our DAkkS-accredited laboratory, we offer professional calibration of material testing machines that meet the highest precision standards.

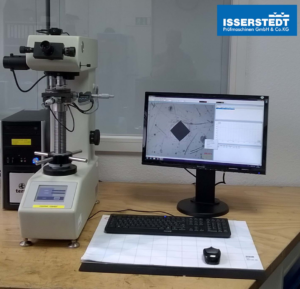

Modernization and Overhaul

Overhauls of material testing machines with a warranty. Over the past 50 years, it has become evident that tried-and-tested technology in the harsh everyday operations of foundries, heat treatment plants, and similarly demanding environments remains unbeatable in the long term. This is consistently reflected in our customers’ requests to overhaul and digitize their sometimes very old machines.

The Key Benefits of Modernization

- A Significantly Longer Lifespan than Modern Machines

- You know what you're getting back

- The employees are familiar with the technology

- Low investment with high effectiveness

- Durch ein gezielte ModernAchieving a high standard through targeted modernization, enabling integration into production data collectionisierung wird ein hoher Standard erreicht der auch eine Einbindung in die Betriebsdatenerfassung ermöglicht

For the modernization, a hardness testing machine is completely disassembled. We replace worn parts, rework other components, or source replacements. Finally, we reassemble and calibrate the machine, giving it a like-new finish.

Repair and Maintenance

Your problems are our challenge. Call us. Our qualified technicians are happy to assist you with expert advice.

If necessary, we will provide you with spare parts immediately or carry out a repair to ensure uninterrupted operation.

We often assist with a loaner device as well, so you can always perform precise testing.

We supply spare parts and accessories for all common material testing machines:

- Hardness Testing Machines

- Charpy Impact Testing Machines

- Notch Impact Testing Machines

- Tensile Testing Machines

- Tear Testing Machines

- Compression Testing Machines

- Bending Testing Machines

In our range, you will also find:

- Hardness Comparison Plates

- Indenters and Testing Diamonds

- Clamping Jaws

- Force Application Components